Recognizing the Value of Professional Stretch Wrap Machine Repair Service for Optimal Efficiency

Stretch Wrap devices play an important function in the performance of manufacturing and logistics operations. However, they can experience breakdowns that interrupt process. Acknowledging these concerns early is vital for decreasing downtime. Expert fixing services supply a solution, but many business neglect their value. Recognizing the benefits of prompt repairs can substantially impact functional performance and cost administration. What elements should services think about when looking for specialist repair solutions for their stretch Wrap machines?

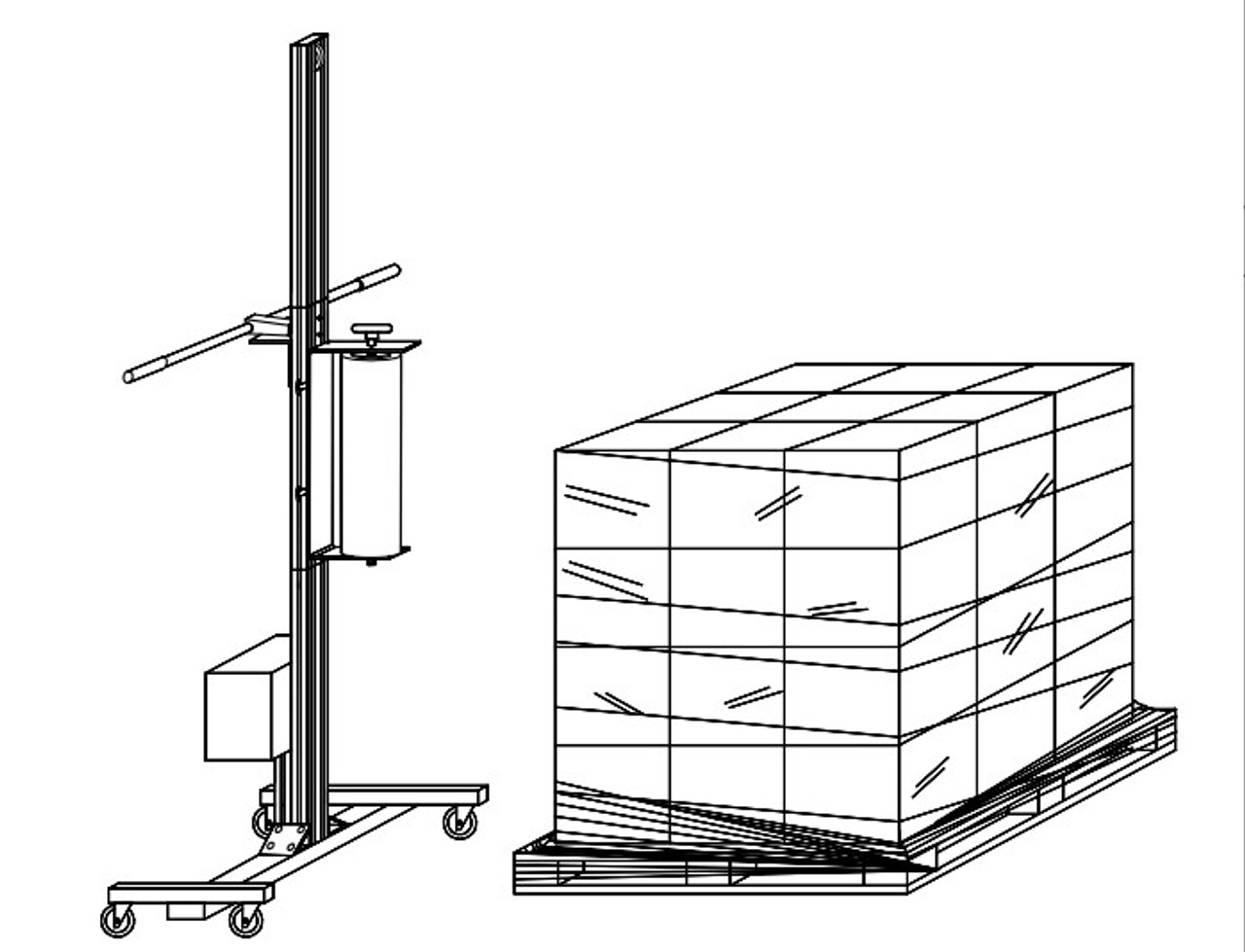

The Role of Stretch Wrap Machines in Production and Logistics

Stretch Wrap devices play an important function in the performance of manufacturing and logistics operations. These equipments automate the procedure of safeguarding products on pallets, improving stability throughout transport and storage space. By tightly covering products in plastic movie, stretch Wrap devices minimize the threat of damage caused by shifting or outside impacts. This not only secures the integrity of the products yet also decreases waste and the need for extra product packaging materials.In production environments, stretch Wrap equipments add to structured operations, permitting faster packaging and delivery processes. They allow business to handle higher quantities of goods, improving general productivity. In logistics, making use of stretch Wrap makers assures that products are adequately protected for transport, decreasing the likelihood of item loss or damages in transit. By optimizing lots security, these devices inevitably support affordable procedures, making them indispensable properties in modern supply chains.

Common Signs of Stretch Wrap Machine Breakdown

When a stretch Wrap Machine begins to malfunction, specific indicators can indicate the need for instant focus. One common indicator is inconsistent wrapping stress, which might bring about loose or extremely limited wraps, jeopardizing item security. Additionally, uncommon noises throughout operation, such as thumping or grinding, can indicate mechanical problems that require examination. A decrease in covering rate or failure to complete cycles can likewise indicate underlying troubles, potentially resulting in functional delays. One more indication is the existence of film jams, where the covering product ends up being stuck, interrupting the workflow. These informs must not be ignored if the Machine presents mistake codes or cautioning lights on its control panel. Visible wear on elements, such as rollers or movie dispensers, may suggest that maintenance or repair work is necessary to bring back peak capability. Identifying these indications early can prevent further issues and guarantee effective procedure.

The Impact of Downtime on Procedures

Downtime of stretch Wrap devices can greatly affect a firm's monetary efficiency, bring about substantial financial losses. Furthermore, manufacturing delays might interfere with supply chains and consumer contentment, additional worsening the effect on procedures. Comprehending these consequences is essential for efficient Machine maintenance and repair service strategies.

Financial Loss Assessment

The impact of equipment failing can substantially interfere with operations, bring about considerable financial losses. When a stretch Wrap Machine malfunctions, production may stop, resulting in unfinished orders and disappointed consumers. This downtime not only influences instant profits however can additionally harm lasting organization partnerships. The costs associated with repair work, combined with shed productivity, can quickly build up, stressing spending plans. Furthermore, companies might sustain additional expenses from overtime incomes for personnel who need to compensate for shed time once the Machine is functional again. In an open market, such economic effects can impede a business's development and profitability. Specialist and timely repair solutions are crucial to lessen downtime and protect financial health.

Production Hold-ups Repercussions

Equipment failure can lead to substantial production hold-ups, influencing different aspects of operations. When a stretch Wrap Machine breakdowns, the immediate consequence is stopped packaging procedures, which can develop a stockpile in production timetables. This interruption not only affects the circulation of goods yet likewise strains labor sources, as workers might be compelled to stand still or redirect initiatives to other tasks. Hold-ups can result in unmet delivery due dates, staining customer partnerships and potentially leading to shed sales. In addition, downtime incurs additional prices associated with fix solutions and overtime earnings for workers. Inevitably, the surge effect of production hold-ups highlights the crucial need for expert and prompt upkeep of stretch Wrap equipment to guarantee seamless operational connection.

Advantages of Expert Repair Work Services

Specialist fixing services for stretch Wrap equipments provide several vital advantages. These solutions not just improve tools durability yet additionally contribute to boosted operational effectiveness and offer cost-effective maintenance solutions. By spending in professional repairs, services can guarantee their equipments execute at peak performance gradually.

Boosted Tools Durability

Buying professional repair service services for stretch Wrap machines substantially enhances their durability. Regular upkeep and prompt repair services resolve prospective concerns prior to they escalate, making sure that devices run at their best. Competent professionals utilize specialized expertise and devices to identify and correct troubles that may not be evident to inexperienced drivers. This proactive technique decreases damage, thus extending the life expectancy of the devices. In addition, making use of top quality replacement parts during repairs better adds to longevity. Consequently, companies can avoid the costs connected with early equipment failure and substitute. On the whole, expert repair solutions play an essential role in maintaining the stability and functionality of stretch Wrap equipments, inevitably guarding their long-lasting investment.

Increased Functional Effectiveness

Keeping stretch Wrap devices via specialist repair service services substantially boosts functional efficiency. Specialist fixing warranties that all elements function at their finest, reducing the likelihood of breakdowns that interrupt production routines. When equipments remain in peak problem, they can operate at their created rate and precision, causing faster wrapping processes. This performance reduces downtime and permits for smoother operations, inevitably enhancing efficiency. On top of that, properly maintained makers require less power to operate, contributing to enhanced source management. By addressing mechanical concerns quickly, expert repair services prevent minor issues from rising right into significant failings, guaranteeing that operations run seamlessly. Business can accomplish higher outcome levels, fulfill customer needs a lot more effectively, and maintain a competitive side in the market.

Cost-efficient Upkeep Solutions

A well-executed repair service can substantially decrease long-term maintenance costs for stretch Wrap devices. By dealing with issues without delay and successfully, specialist fixing solutions reduce the danger of comprehensive damage that might demand costly replacements. Regular upkeep and timely repair work ensure that devices operate at peak effectiveness, decreasing energy usage and material waste. In enhancement, skilled professionals have the competence to recognize underlying problems that may not be immediately noticeable, stopping future malfunctions. Purchasing expert repair work solutions likewise extends the life expectancy of the tools, supplying significant cost savings over time. On the whole, these economical maintenance options not only boost the performance of stretch Wrap equipments but likewise add to an extra lasting functional spending plan.

Preventative Maintenance for Stretch Wrap Machines

Integrity in stretch Wrap machines rests on efficient preventative maintenance techniques. Normal upkeep is necessary to assure peak efficiency and longevity of the equipment. This includes regular assessments, lubrication of moving components, and timely replacement of see here now worn parts - stretch wrap machine repair near me. By sticking to an organized upkeep schedule, drivers can determine prospective issues prior to they rise right into significant issues, consequently decreasing downtime and expensive repairs.Additionally, cleansing the Machine from debris and deposit is important, as it visit this web-site can affect functionality and rate. Operators needs to likewise keep track of the stress on the wrapping movie and change settings as needed to avoid movie breakage and warranty safe and secure loads. Training staff on proper operation and upkeep methods further boosts dependability. Eventually, applying a comprehensive preventative maintenance plan not just prolongs the life of stretch Wrap makers yet likewise adds to the general performance of product packaging operations

Choosing the Right Repair Work Solution for Your Equipment

Frequently Asked Inquiries

Just How Usually Should Stretch Wrap Machines Be Checked for Upkeep?

Stretch Wrap makers should be inspected for upkeep at the very least every 6 months (stretch wrap machine repair near click over here me). Regular evaluations help determine prospective concerns early, guaranteeing the machines run efficiently and minimizing the threat of expensive downtime or extensive repair services

Can I Carry Out Repair Services on My Stretch Wrap Machine Myself?

While some small changes may be possible, trying extensive repair work on a stretch Wrap Machine can result in more complications. It is normally a good idea to get in touch with an expert service technician for secure and efficient fixing solutions.

What Is the Average Lifespan of a Stretch Wrap Machine?

The ordinary lifespan of a stretch Wrap Machine usually varies from 5 to one decade, depending on use intensity, maintenance practices, and the quality of the Machine, affecting its overall efficiency and sturdiness gradually.

Exist Particular Brand Names Understood for Better Longevity in Stretch Wrap Machines?

Particular brand names, such as Signode and 3M, are recognized for their resilience in stretch Wrap machines. Consumers often report much longer life expectancies and less upkeep issues contrasted to other brand names, making them prominent options in the sector.

Exactly How Can I Tell if My Machine Needs an Upgrade As Opposed To Fixing?

Indicators for upgrading a stretch Wrap Machine include regular malfunctions, outdated technology, increasing functional expenses, and lack of ability to meet manufacturing needs. Examining efficiency metrics can help establish whether fixing or upgrade is the much more sensible choice - stretch wrap machine repair near me. By tightly wrapping goods in plastic movie, stretch Wrap makers lessen the risk of damages caused by changing or exterior impacts. Specialist repair service services for stretch Wrap makers use several vital advantages. Spending in professional fixing services for stretch Wrap equipments significantly improves their longevity. Preserving stretch Wrap equipments through professional repair work services substantially boosts operational performance. A well-executed repair work solution can greatly minimize long-term upkeep expenses for stretch Wrap equipments